Mô tả

IEP Technologies Explosion Vents—also called explosion relief panels or rupture panels—are devices that release pressure and flame from a dust explosion. The purpose of a vent is to create a discharge path for the flame and expanding gases, preventing the dangerous buildup of pressure inside equipment. This minimizes equipment damage and helps protect personnel working around the machinery.

- Overview of IEP Technologies Explosion Vent Panels

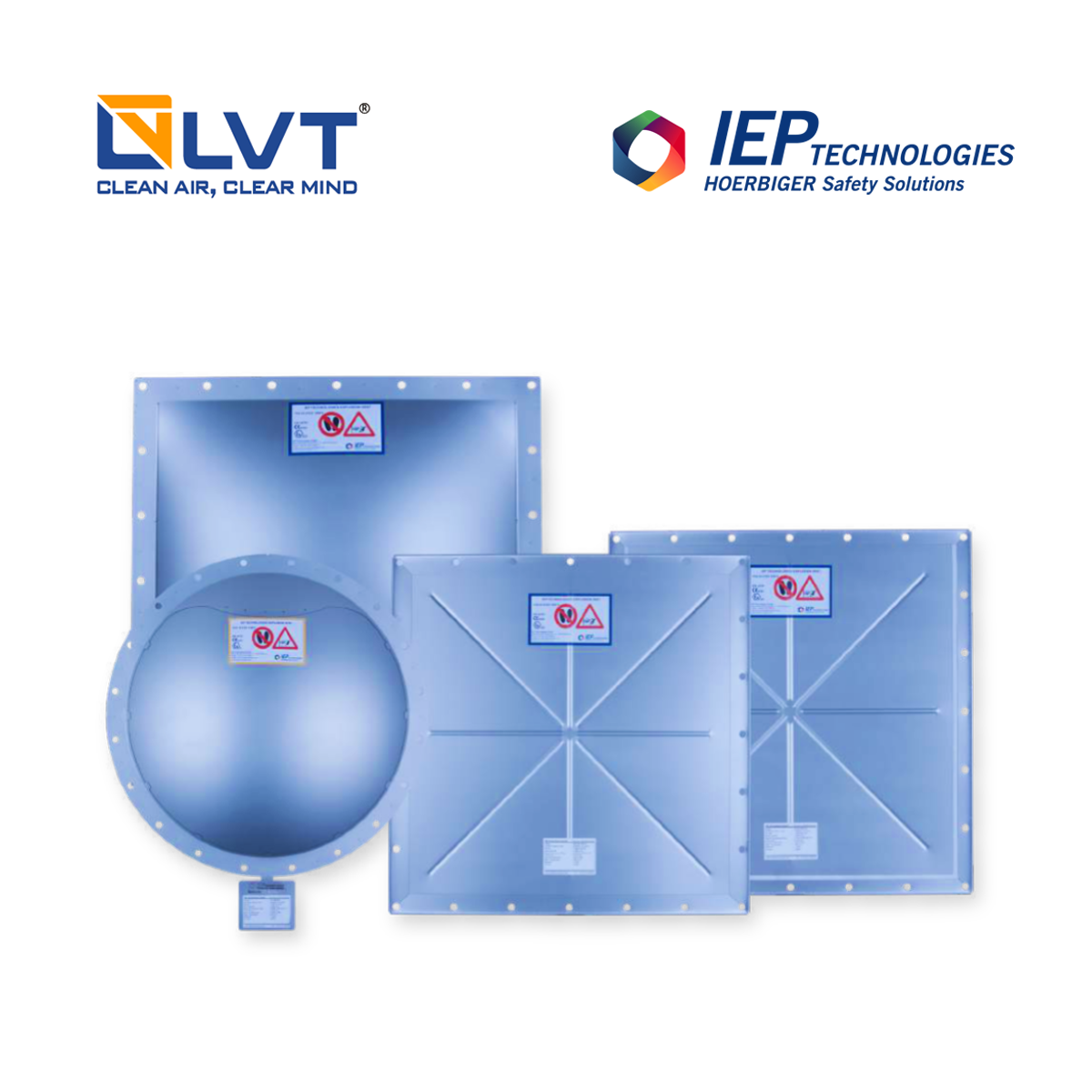

IEP Technologies’ explosion vent panels are designed to open at a predetermined pressure, allowing the fireball and explosion pressure to be directed to a safe area. Vents are available in a wide range of sizes, configurations, and opening pressures. Depending on the specific application, vents are offered in flat, multi-layer, and domed designs to provide a protection solution suited to each equipment type.

- Types of Explosion Discharge Devices

There are two main categories of explosion discharge devices:

- Explosion vents/vent panels (fixed, non-resettable): These are designed to open (rupture) once and cannot be reset. When they open, they are positioned to direct the fireball to a pre-engineered safe location, which may be outside the building or away from structures.

- Flameless venting devices (often called “indoor vents”): These are used on equipment located indoors and quench the flame within the device itself. A key advantage is that they can be inspected, reset, and put back into service after activation.

- Construction and Applications of IEP Technologies Vent Panels

2.1. Construction of IEP Technologies Vent Panels

Explosion venting is a widely used method to minimize or redirect the explosion fireball to a safe location. IEP vents are manufactured in stainless steel and can include options such as:

- Insulation cover

- Round or rectangular shapes

- Flat or domed geometry, depending on operating pressure

- Hygienic/clean installation at the designated mounting location

- Integrated flange gaskets

- Temperature resistance

- Mounting frames

Rupture/activation sensors: Each vent can be equipped with a sensor that sends a signal—via wired connection to a central control panel—to alert operators that an explosion event has occurred. When the vent activates, the indicator transmits a signal back to the central panel to trigger alarms such as lights and/or sirens. This signal can also be used to shut down equipment.

2.2. Typical Applications

Common uses for IEP explosion vents include:

- Dust collectors—baghouse, cartridge filters, and cyclones

- Storage silos or tanks

- Vacuum dust collection systems

- Storage vessels or material conveying systems

- Bucket elevators

- Dryers

- IEP Technologies Vent Types

- Explosion Vent – GE (rectangular and round)

Filters with pneumatic pulse cleaning and high vacuum operation require a vent that can withstand significant vacuum as well as positive pressure over extended periods. For these demands, the GE series is the best choice. Its domed design tolerates negative pressure without additional vacuum supports. Standard features include resistance to pressure spikes and integrated flange gaskets.

- Explosion Vent – KE

If the negative pressure does not exceed 60% of the rated opening pressure, installing a domed vent offers no added benefit. For such applications, the KE series is an alternative to the domed GE. KE provides long-term durability and aerodynamic advantages compared to domed designs—for example, in cyclones. Resistance to pressure spikes, integrated flange gaskets, cross-ribs, and folded edges are standard KE features.

- Explosion Vent – KER

The KER vent is ideal for standard applications in powder handling and storage. KER suits plant equipment with static over/under-pressure up to 50% of the vent’s rated pressure. A unique feature is its reinforced edge, which enables installation without an outlet flange, reducing installation cost. Cross-ribs and folded edges are additional standard KER design elements.

- Explosion Vent GT

Round GT vents are engineered specifically for applications requiring higher Pstat. Processes with elevated operating pressures may need vents with a static opening pressure above the typical 0.1 barg. The GT range is available from DN 200 mm to DN 1100 mm and can be configured with Pstat up to 0.5 bar, even at elevated process temperatures.

All IEP Technologies explosion protection systems and propagation-prevention devices are highly effective in stopping dust explosions from escalating—from initial ignition through to secondary explosions—across related production equipment and areas. Together with IEP’s engineering expertise, LVT Vietnam supports customers in designing and installing explosion-propagation protection to complete your facility’s explosion safety system.

LVT Vietnam is proud to be the official distributor of IEP Technologies in Vietnam. We are ready to answer your questions and provide the most optimized solutions for your needs.

Contact us today for consultation and installation!

LVT VIETNAM CO., LTD

Address: Cluster 3, Hong Van Commune, Ha Noi City, Vietnam.

- Hanoi Office: No. 7, Lot L-4, Ba Da Area, Binh Vong, Thuong Tin Commune, Hanoi City

- Da Nang Office: No. 33, Hoa Minh 22 Street, Hoa Khanh Ward, Da Nang City.

- HCMC Office: A2.11.05 Green Sapphire Tower, 57 Thong Nhat Str. Dong Hoa Ward, HCMC.

Hotline: 024 3685 6633 – 0904 667 286

Email: lvtvietnam@gmail.com / thanh.le@lvtvietnam.com.vn

Website: https://lvtvietnam.com.vn/ or https://lvtvietnam.com/

Đánh giá

Chưa có đánh giá nào.